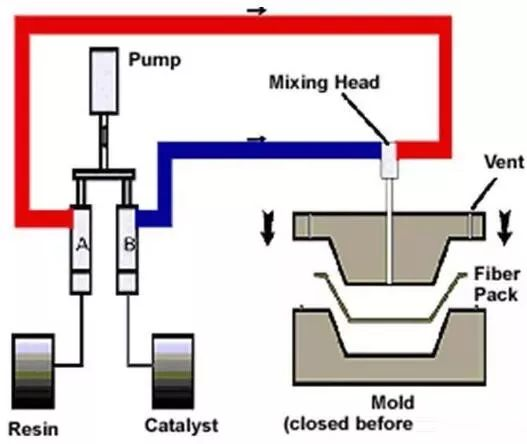

RTM refers to a process technology in which low-viscosity resin flows in a closed mold, infiltrates reinforced materials and solidifies into shape. It belongs to the category of liquid forming or structural liquid forming technology of composite materials. The specific method is to pre-place reinforced materials that have been rationally designed, cut or mechanized pre-formed into the designed mold. The mold needs to be sealed and tightened around the perimeter to ensure smooth resin flow. After the mold is closed, a certain amount of resin is injected. And after the resin solidifies, the desired product can be obtained by demoulding.

The RTM molding process has the following main characteristics

- RTM is a closed mold molding process. The infiltration of the reinforcement and the resin is completed by the rapid flow of pressurized resin in a closed mold cavity, instead of manual infiltration in hand lay-up and spraying processes, nor expensive mechanized infiltration in prepreg and SMC processes. RTM is a low-cost, high-quality semi-mechanized fiber/resin impregnation method.

- The RTM molding process uses reinforced material preform technology that is similar to the shape of the product. Once the fiber/resin infiltration is completed, it can be cured, so a low-viscosity fast-curing resin system can be used. It can also heat the RTM mold to further improve production efficiency and product quality.

- The reinforced material preform in the RTM molding process can be prepared from chopped strand mat, fiber cloth, wrinkle-free fabric, three-dimensional knitted fabric, three-dimensional braided fabric, etc. And according to the performance requirements, selective reinforcement, local reinforcement, hybrid reinforcement, and embedded and sandwich structures can be used, which can give full play to the performance designability of FRP/composite materials.

- The closed-mold resin injection method of the RTM molding process can greatly reduce the toxicity of harmful resin components to the human body and the environment, and meet the increasingly stringent restrictions on the volatilization concentration of harmful gases such as styrene in advanced industries.

- The RTM molding process generally adopts a low-pressure injection process, which is conducive to the preparation of complex overall structures with large sizes, complex shapes, and two-sided surfaces.

- According to the requirements of the production scale, RTM molds can be selected from different grades of molds such as polyester molds, epoxy molds, surface nickel-plated material molds, alloy molds, aluminum molds and steel molds to reduce costs.

Requirements of RTM technology on epoxy resin systems

- Epoxy resin has low viscosity at room temperature or lower temperature, and has a certain storage period.

- Epoxy resin has good wettability, matching and adhesion to reinforced materials.

- The epoxy resin system has good curing reactivity and does not produce volatile matter and other undesirable side reactions during the curing reaction. The curing temperature should not be too high, and the curing speed should be appropriate.

- As a high-performance composite material, epoxy resin is also required to have high heat resistance and moisture resistance, excellent mechanical properties, especially toughness. In some special applications, it should also have certain functionalities, such as low dielectric loss, high conductivity, excellent flame retardancy, etc.

High-performance epoxy resin system is still the most widely used high-performance composite matrix. Epoxy resin systems usually used to make prepregs are difficult to mold using the RTM process due to their high viscosity and short storage life. In order to be suitable for RTM molding, YQXPOLYMER launched the 9320A/B epoxy resin curing system. 9320A/B is a special epoxy resin curing system for RTM process. This system product is composed of special epoxy resin and modified amine curing agent. The 9320A/B epoxy resin curing system has the characteristics of fast curing speed, good water resistance, high hardness, good adhesion, mechanical properties of the cured material and high Tg temperature. It can be widely used in automotive composite materials for RTM molding, cultural and sports products (fishing rods, badminton rackets, golf clubs, etc.) and other carbon fiber composite materials. The RTM process has a wide range of advantages. The molded parts have high fiber system content, low porosity, low water absorption, and good mechanical properties. Conventional resins and reinforcing materials can be used in the RTM process.

More information or free samples or price quotations, please contact us via email: sales@yqxpolymer.com , or voice to us at: +86-28-8411-1861.

Some pictures and texts are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us to delete.