Introduction

Pultruded epoxy resin composites have revolutionized modern industries by combining superior mechanical properties with versatility and sustainability. These advanced materials offer unique benefits such as high strength, lightweight structure, and excellent corrosion resistance, making them indispensable in various applications.

Key Features of Pultruded Epoxy Resin Composites

- High Strength and Lightweight

Epoxy resin composites deliver exceptional mechanical strength while maintaining a low weight. This characteristic improves overall product performance and reduces energy consumption, especially in industries like aerospace, automotive, and construction.

- Superior Corrosion Resistance

These composites withstand harsh chemical environments, ensuring durability and a long lifespan. Their ability to resist corrosion makes them ideal for challenging conditions in marine, industrial, and environmental applications.

- Excellent Processing and Manufacturing Efficiency

Pultrusion technology enables continuous, high-speed production with consistent quality. It allows for uniform coating thickness and the ability to manufacture complex shapes and sizes, meeting diverse design requirements.

- Stability and Reliability

Epoxy resin composites exhibit excellent dimensional and thermal stability. Once cured, they form a robust structure capable of maintaining performance under varying temperatures and environmental conditions.

- Flexible Design Options

The properties of pultruded epoxy resin composites can be customized to meet specific needs. By modifying resin formulations and adjusting the type and quantity of reinforcement materials, manufacturers can create tailored solutions for various applications.

- Environmental Benefits

The pultrusion process is eco-friendly, as it avoids solvent use and minimizes environmental impact. Additionally, epoxy resin composites can be recycled, supporting sustainability initiatives.

Applications of Pultruded Epoxy Resin Composites

The unique properties of epoxy resin composites make them highly versatile, with applications spanning multiple sectors:

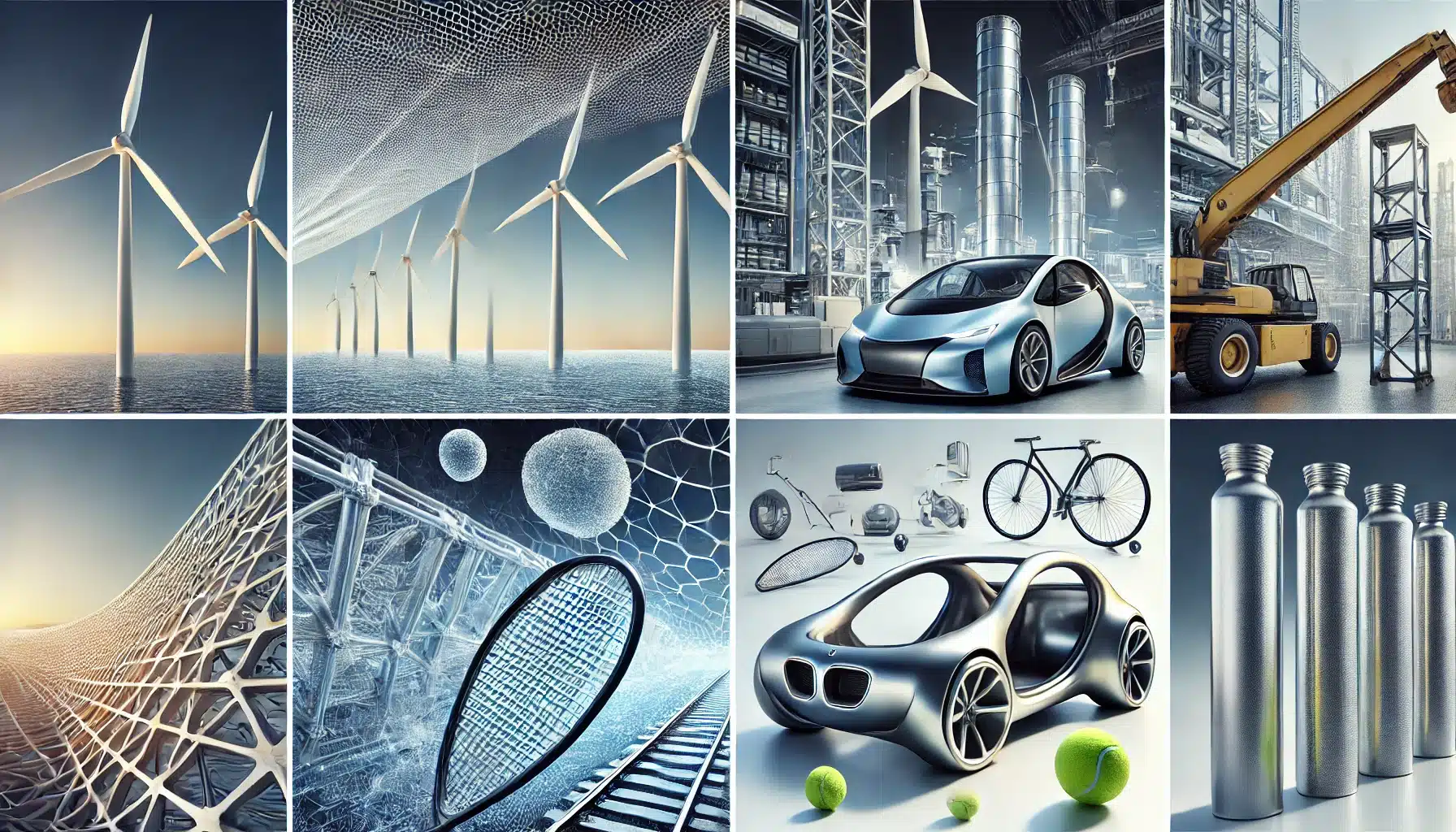

- Wind Energy: Utilized in turbine blades for their lightweight and high strength.

- Transportation: Enhances fuel efficiency in vehicles due to reduced weight.

- Construction: Offers corrosion-resistant solutions for infrastructure, such as bridges and pipelines.

- Sports Equipment: Used in the manufacturing of lightweight, durable sporting goods.

With technological advancements, the potential for these materials continues to grow, opening doors to even broader applications.

Conclusion

Pultruded epoxy resin composites combine unmatched performance with eco-friendly advantages. Their lightweight strength, durability, and versatility position them as the material of choice across numerous industries. As technology evolves, these composites will undoubtedly play an even larger role in shaping sustainable, high-performance solutions.

Explore how pultruded epoxy resin composites can transform your projects. Contact us for more information!

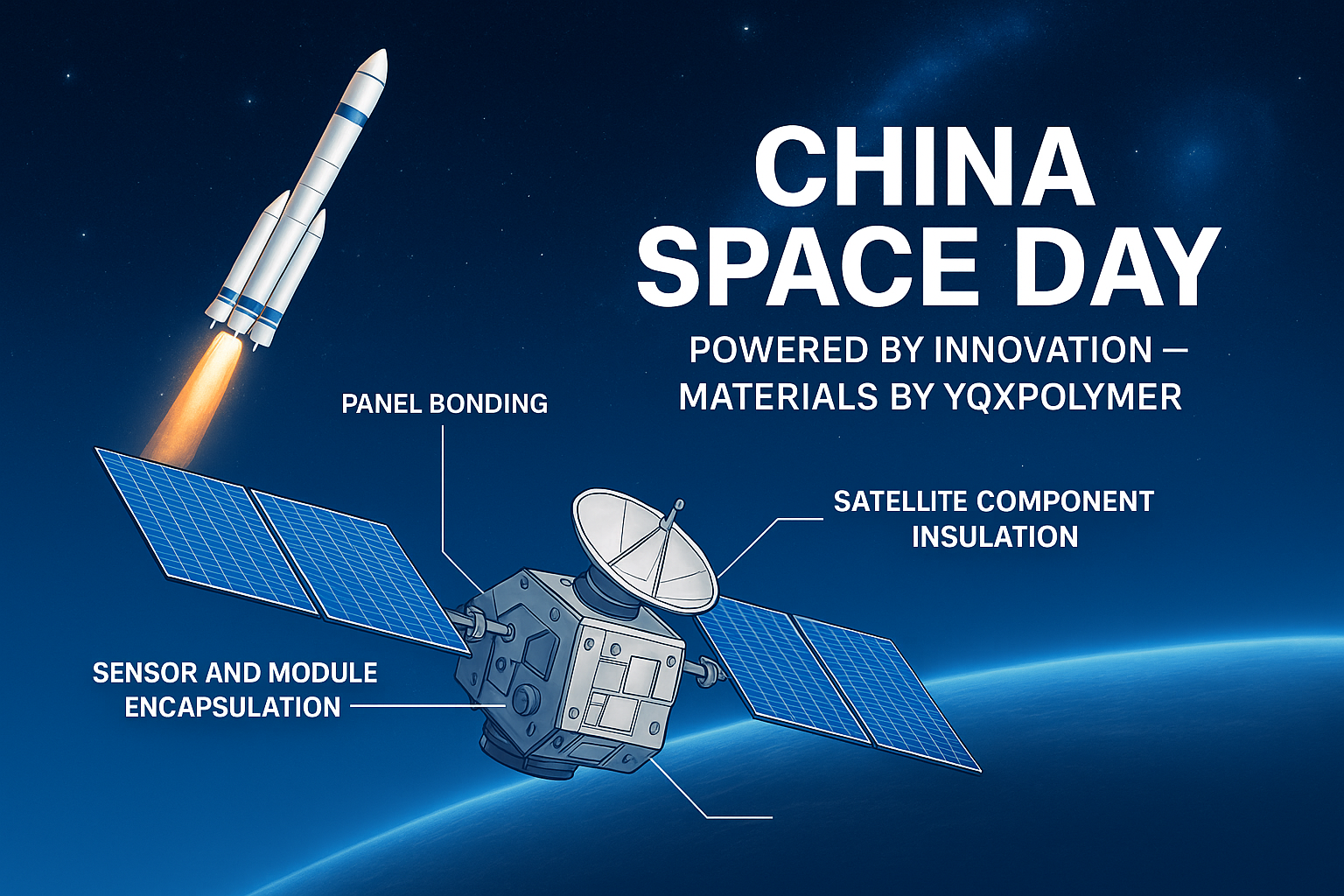

For more information about epoxy resin from YQXPOLIMER, please reach us at: sales@yqxpolymer.com or +86-28-8411-1816.

Some pictures and texts are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us to delete.