Heat-resistant epoxy resin adhesive is an adhesive formulated with modified epoxy resin. It can be used intermittently at 250°C, and can even be used at 400°C for a long time and at 460°C for a short time. The matrix resin of this kind of adhesive generally introduces more rigid groups or increases the cross-linking density of the cured product. For example, epoxy resins with fluorenyl groups, naphthalene rings, multifunctional epoxy resins, or epoxy resin adhesives modified with maleimide or silicone can meet the requirements of short-term high temperature resistance and high strength at 460°C.

In recent years, with the development of electronic appliances and aerospace industries, the requirements for high temperature resistance and ablation resistance have become increasingly higher. When an aircraft flies at high speed in the atmosphere, the temperature sometimes reaches thousands of degrees due to aerodynamic heating, and even the most heat-resistant metal materials must be melted. Therefore, to reduce weight, high temperature resistant composite materials are generally used to replace metal materials. Even in the electronic and electrical industry, sealants with a high temperature resistance of 350°C have been proposed, and flame-resistant insulating adhesives with a temperature resistance of 500 to 1000°C have been proposed.

The modified epoxy resin adhesive and the preparation method overcome the disadvantages of brittleness and poor temperature resistance of general epoxy adhesives. Its main technical feature is to polyurethane prepolymer modified epoxy resin (A component) and homemade curing agent (B component) according to the ratio of 10:1 ~ 1:1 (weight ratio) formulated into a high temperature resistance, good toughness, reactivity curing system. One of the polyurethane prepolymer for the end of the hydroxyl polysiloxane and diisocyanate according to a certain proportion of the reaction under certain conditions to make isocyanate groups capped polysiloxane polyurethane prepolymer. This polyurethane prepolymer is then used to modify the epoxy resin. The homemade curing agent consists of diamines, imidazoles, silane coupling agents, inorganic fillers, and catalysts. This modified epoxy resin adhesive can be cured at room temperature, can be used for a long time at 200 °C, or -5 °C curing temperature resistance of 150 °C; adhesive strength of 15-30Mpa; T-type peel strength of 35-65N/cm. has excellent resistance to oil, water, acid, alkali, organic solvents, can be bonded to wet surfaces, oil surfaces, and metals, plastics, ceramics, hard rubber, wood and so on.

To improve the strength of epoxy resin, a second component is generally added to toughen the resin and improve the toughness of the epoxy resin. According to reports, the main ones include liquid toughening, toughening, elastic microsphere toughening, thermotropic liquid crystal (TLCP) toughening, polymer blending, copolymerization modification, etc.

Toughening modification of liquid rubber generally refers to the liquid nitrile rubber and poly containing terminal carboxyl group, amine group, hydroxyl group, thiol group, epoxy group, etc., which are miscible with epoxy resin and precipitated during curing, forming a two-phase structure of the “island model”, and through the interaction of reactive groups, a chemical bond is formed on the interface of the two phases and plays a toughening role. In recent years, in addition to the use of pure reactive liquid rubber pre-reaction additives, has developed to the second generation of high functionality epoxy resin and the third generation of metallocene catalysts used in the preparation of block copolymer-modified epoxy prepolymer, through which the modification not only improves the peel strength, but also the overall mechanical properties and thermal properties have not been significantly reduced.

Polyurethane toughened epoxy adhesive is through the formation of polyurethane and epoxy resin semi-interpenetrating network polymer (SIPN) and interpenetrating network polymer (IPN), playing a forced mutual solubility and synergistic effect, so that the high elasticity of the polyurethane and the epoxy resin with good adhesion organically combined, through the complementary and reinforcement to achieve a good toughening effect.

One-component room temperature wet curing epoxy adhesive is a kind of epoxy adhesive cured with modified ketoimide as curing agent, which is characterised by the fact that it can be cured under humid and low temperature conditions, and it can improve the temperature resistance and corrosion resistance of epoxy resin cured products. Phenolic modified ketoimine curing agent, it is first by, formaldehyde, m-phenylenediamine reaction to generate phenolic amine, and then with methyl isobutyl ketone reaction to generate phenolic modified ketoimine. At present, domestic efforts are being made to study the low-temperature, low-humidity rapid curing epoxy adhesive speed curing technology. At present, the domestic development of two-component room temperature curing epoxy adhesive, can withstand temperatures of 200 ~ 260 °C, up to 275 °C, 25 °C 2 ~ 6min to gel, fully cured 3 ~ 8h, polyether diamine curing peel strength can reach 4 ~ 5kN/m.

Low-temperature fast-curing epoxy adhesive is formulated by the bisphenol F epoxy resin, it and diphenyl phosphite decyl ester, DMP-30, etc., with the -5 °C temperature can be quickly cured, has been developed and applied to the field of civil engineering and construction. Mainly used for concrete “whole project” bonding, building repair, product repair and construction materials bonding. In the construction project, it can replace the rivets, welding, and other structural jointing process, used for bonding a variety of marble and artificial plates.

High-strength composite material repair technology is the future development trend of repair technology for the external anti-corrosion layer of oil and gas pipelines. It is a technology that uses a high-performance resin matrix to bond reinforced materials to form a protective structure, so it has high compressive strength, tensile strength, and bonding force. There is no need to shut down the pipeline or depressurize the pipeline during repair construction. It also has the advantages of simple and convenient operation, easy training of construction personnel, good reinforcement effect and significant economic benefits. Composite material repair technology can be used for on-site winding construction and on-site curing. The construction process is open flame, safe and convenient. Thirdly, the strength of composite materials reinforced with glass fiber, carbon fiber or fabric is much higher than that of ordinary steel, making composite materials more efficient in repair and reinforcement. Composite materials are designable and can be designed in thickness, number of layers, fiber distribution, etc. according to the degree of defect damage and stress conditions, and their repair reliability is high. The interlayer adhesive of glass fiber or carbon fiber reinforced resin-based composite materials has good interfacial adhesion, sealing and excellent corrosion resistance with metal, which can greatly reduce secondary corrosion damage during the operation period of pipelines. In composite material repair technology, the selection of adhesive has a crucial impact on its protective performance.

When polyurethane toughens and modifies epoxy resin adhesives, the polyurethane segments penetrate the epoxy resin segments to form an interpenetrating polymer network structure (IPN) or a semi-interpenetrating polymer network structure (SIPN). Because polyurethane and epoxy resin have different solubilities, IPN materials show varying degrees of phase separation. However, due to the entanglement between networks, “forced mutual dissolution” occurs, which increases compatibility. And once the polymer is cross-linked, the entangled network fixes the phase area. Since the polyurethane particles are dispersed in the continuous epoxy resin phase, the toughness of the system is increased, the stress concentration of the cured product is dispersed, and the shear strength is increased. As the amount of polyurethane added increases, the shear strength gradually increases, but when the polyurethane content exceeds 13.04%, the degree of interpenetration of the interpenetrating polymer network structure formed by polyurethane/epoxy resin has reached saturation. If the amount of polyurethane is further increased, the interpenetrating polymer network will experience excessive interpenetration, the polyurethane and the epoxy resin will separate, form cracks, and the compatibility of the polyurethane and the epoxy resin will decrease sharply. Therefore, in terms of shear strength, the optimal polyurethane dosage is 13.04%. The peel strength is mainly related to the bonding performance and flexibility of the epoxy resin adhesive. The changing pattern of the interpenetrating polymer network structure system formed by polyurethane and epoxy resin shows that as the amount of polyurethane added increases, the flexibility of the cured product first increases and then decreases. Therefore, the peel strength of epoxy resin adhesive will first increase and then decrease as the amount of polyurethane added increases. When the polyurethane reaches 20%, the peel strength begins to decrease with the increase in the amount of polyurethane added. Therefore, the optimal polyurethane dosage for peel strength is 20%.

Among the many epoxy resin toughening techniques, the toughening effect of elastomers represented by polyurethane is the most significant. However, epoxy resin is a linear thermoplastic resin, which will not harden by itself, and can only be cured by adding a curing agent to cross-link it from a linear structure into a mesh or body structure. Therefore, while using polyurethane to toughen the epoxy resin, it is necessary to add a curing agent to make it meet the requirements of curing performance during construction. Epoxy resins contain multiple benzene or heterocyclic rings with small flexible molecular chains. The cured epoxy resin has a high cross-linking structure, the cross-linking structure is not easy to deform, resulting in epoxy resin adhesive has a lack of toughness, easy to brittle cracking, low peel strength and poor impact resistance and other shortcomings, so that its application has been greatly restricted, so the toughening modification of the epoxy resin in the pipeline repair application of great practical significance and its application prospects.

In practice, there is often a need for adhesives that can be cured both at room temperature and at high temperatures. For example, structural adhesives for construction are not only required to be able to withstand high temperatures to prevent the building from collapsing in a fire, but also because of the large bonding area it is not possible to heat cure. However, room temperature curing EP adhesives generally cannot be used at high temperatures, while heat resistant EP adhesives often require heat to fully cure. The so-called room temperature curing, usually refers to can be at room temperature (20 ~ 30 °C) conditions within a few min or a few h gel, and within 7d fully cured, and reach the usable strength of the curing method. Although some progress has been made in room temperature curing, high temperature use of adhesives, but there is still a considerable distance from the need. In the future, we should strengthen the research on the curing mechanism of EP adhesives, develop multifunctional active curing agents; synthesise new multifunctional EP matrix resins, explore new modification methods of EP resins and new types of fillers; and improve the performance of the basis of the research and development of adhesives in the direction of resource-saving, environmentally friendly development.

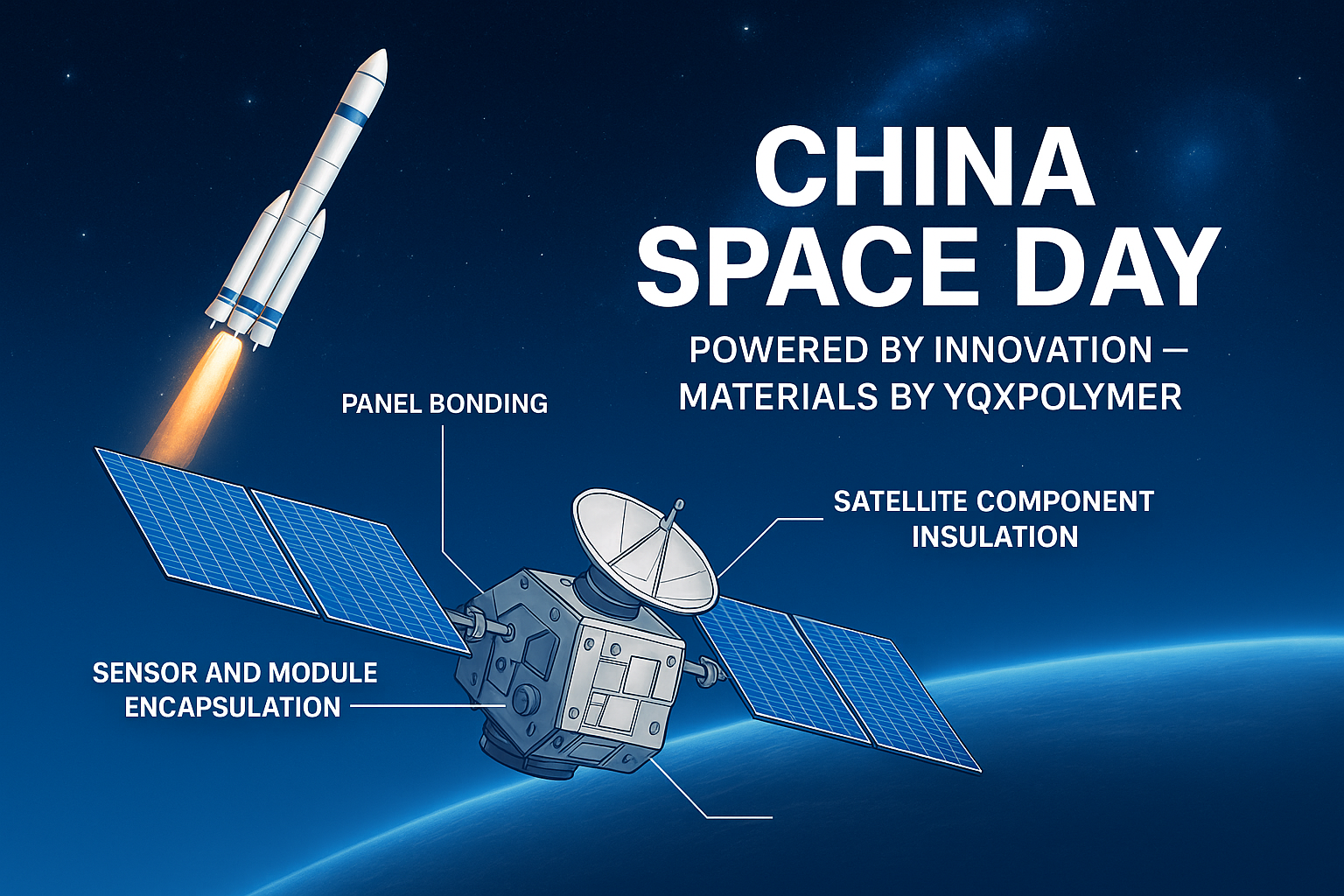

More information or free samples or price quotations, please contact us via email: sales@yqxpolymer.com , or voice to us at: +86-28-8411-1861.

Some pictures and texts are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us to delete.