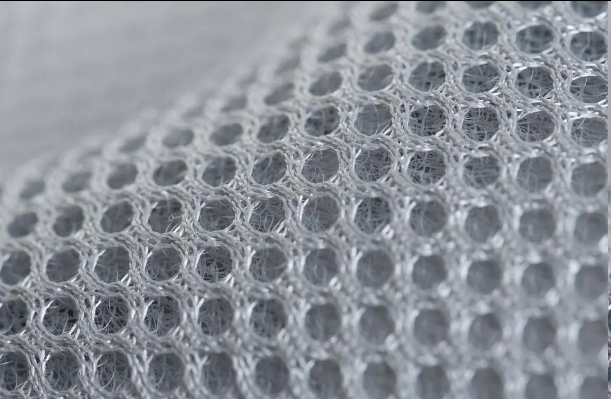

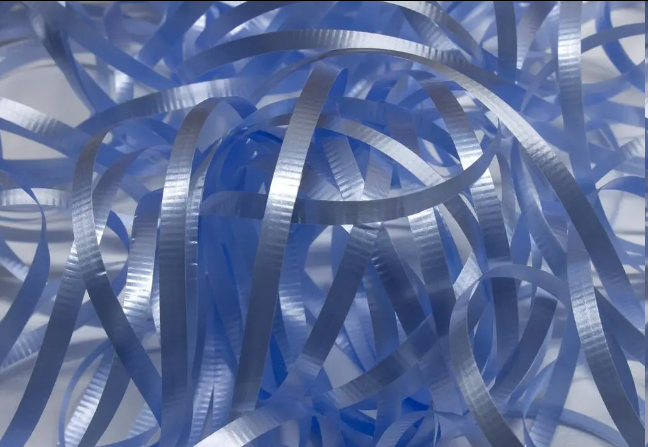

With the continuous development of science and technology, the requirements for material performance are increasing. Carbon fiber reinforced epoxy composites are widely used in aerospace, automotive manufacturing and other fields due to their excellent properties such as light weight, high strength and corrosion resistance. However, a single type of carbon fiber composite may not be able to meet the complex demands of use in some specific environments. Therefore, researchers have begun to explore the blending of different types of carbon fiber composites to obtain more excellent comprehensive performance. One of the important types is the carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites.

Preparation of carbon fiber reinforced epoxy resin three-dimensional woven/unidirectional fabric hybrid composites

The preparation process of carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites includes the steps of raw material selection, fiber pretreatment, fabric weaving, resin impregnation and curing. During the preparation process, the quality of fibers, the weaving structure of fabrics and the ratio of resin need to be strictly controlled to ensure that the properties of the final composites meet the expected requirements.

Mechanical Properties of Carbon Fiber Reinforced Epoxy Resin 3D Woven/Unidirectional Fabric Hybrid Composites

1. Tensile properties

Carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites show excellent mechanical properties under tensile loading. The three-dimensional braided structure can effectively improve the connection strength between the fibers, which makes the composites better resistant to damage when subjected to tensile loads. Meanwhile, the incorporation of unidirectional fabric further enhances the tensile strength of the composites. The experimental results show that the tensile strength of the composite is much higher than that of a single type of carbon fibre composite.

2. Compression properties

The carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites also showed good mechanical properties under compressive load. The three-dimensional woven structure enables the composites to form a more compact fiber network under compression load, which improves their compressive capacity. In addition, the presence of unidirectional fabrics can effectively inhibit the lateral deformation of the composites, which further improves their compressive properties.

3. Flexural properties

The carbon fibre reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites also show better mechanical properties under bending load. Due to the combined effect of 3D woven structure and unidirectional fabric, the composites can better withstand the external force and maintain their structural stability when subjected to bending loads. In addition, the bending stiffness of the composite material is also higher, which can meet the needs of some special occasions.

4. Impact performance

Carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites also show excellent performance under impact loading. The three-dimensional braided structure can effectively disperse the impact energy and reduce the damage of the composite material when it is subjected to impact. At the same time, the addition of unidirectional fabric can also improve the impact resistance of the composite material, so that it can maintain a better integrity during the impact.

Application prospects of carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites

Carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites show a broad application prospect in aerospace, automobile manufacturing, sporting goods and other fields with their excellent mechanical properties. For example, in the field of aerospace, the composite material can be used to manufacture aircraft fuselage, wings and other components to improve the overall performance of the aircraft; in the field of automobile manufacturing, the composite material can be used to manufacture the body, chassis and other components to reduce the weight of the car and improve fuel economy; in the field of sporting goods, the composite material can be used to manufacture the golf clubs, bicycle frames and other products to improve the performance and service life of the products. In the field of sporting goods, the composite material can be used to manufacture golf clubs, bicycle frames and other products to improve product performance and service life.

Carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites, as a new type of high-performance composites, exhibit excellent mechanical properties. Its unique preparation process and 3D woven/unidirectional fabric hybrid structure make the composite material show good performance under tensile, compressive, bending and impact loads. In the future, with the continuous optimization of the preparation process and the expansion of application areas, the carbon fiber reinforced epoxy resin 3D woven/unidirectional fabric hybrid composites will be more widely used and developed.

For more about epoxy resin for coating, please reach us at: sales@yqxpolymer.com or: +86-28-8411-1861.

Some of the illustrations are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us for deletion.