The potting compound industry has become an important area of epoxy resin application. With the accelerated development of the electronics and electrical industries, it will become an important growth point for epoxy resin. However, there are still some problems in the application of epoxy resin as potting materials. Epoxy resin potting materials are mainly used to cast and encapsulate electronic and electrical devices to achieve the performance requirements of insulation, voltage resistance, protection, and sealing. Experts say that the current problems during use are mainly to understand and solve the problems of defoaming of cured materials, selection of curing agents, and filling and use.

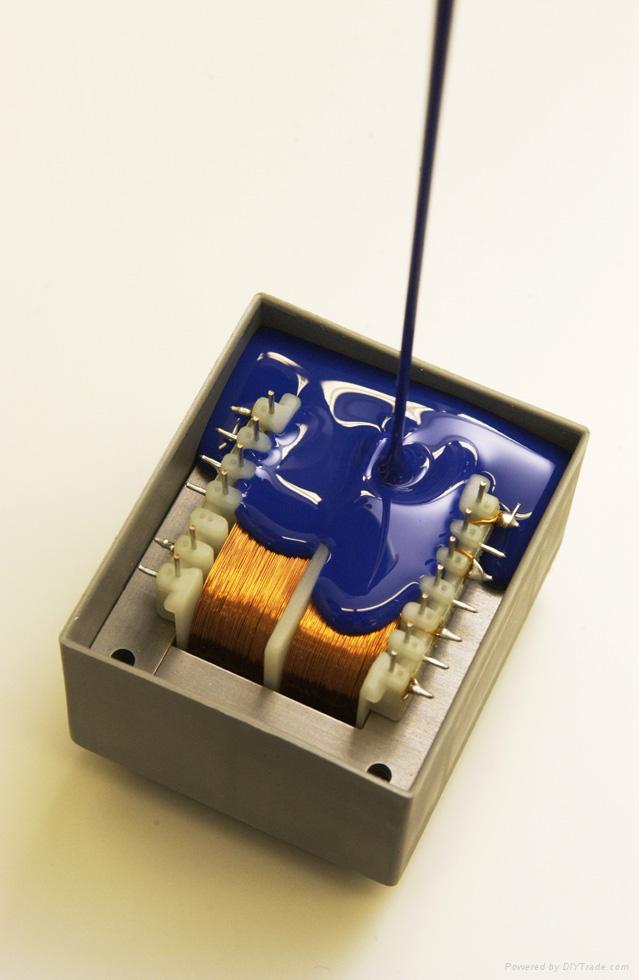

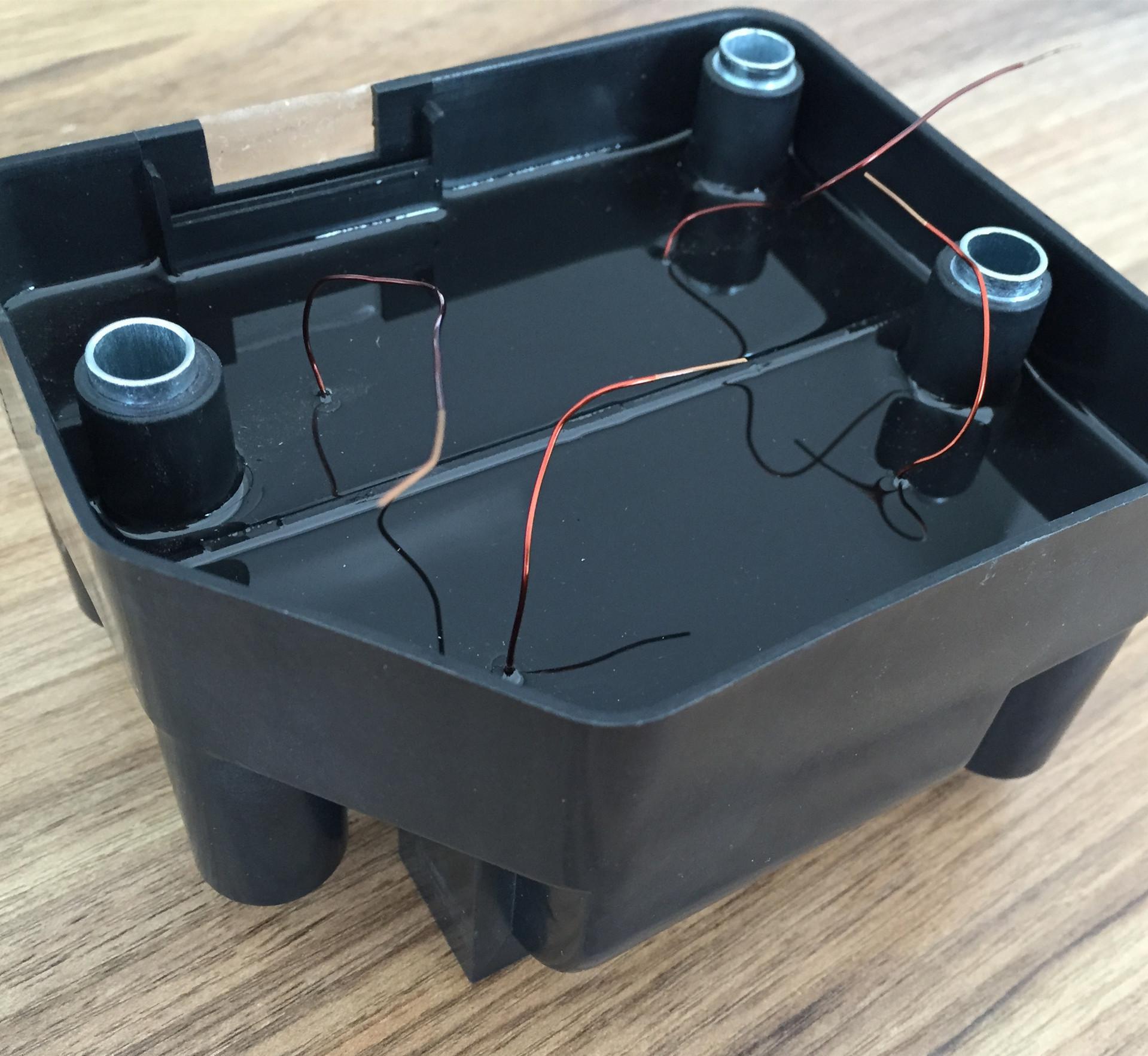

Potting is to pour a liquid compound mechanically or manually into a device equipped with electronic components and circuits, and solidify it under normal temperature or heating conditions to become a thermosetting polymer insulation material with excellent performance. Epoxy resin potting compound is one of the common potting materials.

Epoxy resin is the main component of epoxy resin potting glue. It is generally composed of bisphenol A epoxy resin, curing agent (amine or acid anhydride), reinforcing additives and fillers.

The main advantages of epoxy resin potting glue are low viscosity and strong impregnation, which can fill components and lines. It has good performance and long application period, and is suitable for large-volume automatic production line operations. During the potting and curing process, the filler and other powder components settle little and do not stratify. The curing exothermic peak is low and the curing shrinkage is small; the potting material has properties such as flame retardancy, weather resistance, and thermal conductivity. It has good adhesion to a variety of materials and has low water absorption.

Regarding the problem of defoaming of cured materials: Since the potting material has a certain viscosity, the viscosity gradually increases during the curing and heating process. The bubbles generated by stirring during the production of the potting material burst at the same time as the temperature rises. But there is always a certain amount of foam that will not break, so defoamer and foam suppressor need to be added. The selection of this material is very important, and the amount added is also very important. If it is less, it will not meet the foam breaking requirements, and if it is too much, oil splashes and white spots will occur on the surface of the cured product. At present, some silicone oil-based defoaming agents are mainly used. The disadvantage of this type of defoaming agent is that it is easy to produce oil splashes on the surface of the cured product, that is, there are irregular oily substances on the surface, causing unsightly appearance. This is mainly caused by poor control of the amount of addition. The most important thing is the selection and addition amount of defoaming agent, as well as the addition process.

The choice of curing agent is very important: curing agents are generally divided into medium, low and high temperatures. Different curing agents are used depending on the purpose of epoxy resin potting. Generally, amines, modified amines, polyamides, etc. are used for medium and low temperatures, and acid anhydrides, etc. are used for high temperatures. Different curing agents have different properties and are suitable for different occasions, but the proportion of each curing agent used in the epoxy resin potting system is different. The proportion of pure epoxy in the epoxy potting compound can be calculated first, and then calculated based on the proportion of epoxy resin curing agent. At the same time, the difference between actual and theoretical values needs to be taken into account. The curing temperature can be tested according to the data provided by the curing agent manufacturer, and the usage amount of the entire cured product and the heat of reaction should also be taken into consideration, so as to obtain the optimal curing temperature in the unit mass curing system.

The use of fillers cannot be ignored: some fillers need to be added to the epoxy resin curing system to increase the physical strength of the cured material. The selection of fillers mainly depends on the performance requirements of the cured product. Commonly used fillers include aluminum hydroxide, wollastonite, silica powder, talc powder, quartz sand, etc. Some of the fillers not only play a filling role, but also play other roles, such as flame retardant, preventing sedimentation, etc. The most common problem during the use of fillers is filler settlement, because most fillers are inorganic and difficult to combine well with organic systems. Especially if the product is left for too long, it is more likely to cause the filler in the product to settle. Therefore, the generally used fillers have been organically treated to organicize the surface of the filler, so that it can achieve a good combination with organic materials.

How to use potting glue

After curing, potting glue can improve the integrity of electronic components and make them more like a whole. Effectively resist external shocks and vibrations, relieve all external forces, and play a protective role. Essentially, potting glue is still a glue and is highly viscous. From the perspective of operation methods, there are single-component and two-component ones.

The usage of one-component potting glue is as follows:

Before use, small-scale experiments should be carried out. See if you can exert good adhesion and do a good adhesion test.

Before gluing, be sure to clean the bonding base surface. Cleaning away the dirt will help improve adhesion.

When using a machine for pouring, if you need to stop dispensing midway, you need to prevent the entry of water vapor. Keep water vapor out to avoid affecting the curing speed of the adhesive.

During the curing process, the speed is closely related to the ambient temperature. If you want to speed up the curing speed, you can increase the temperature and humidity appropriately.

Two-component potting AB glue usage instructions:

The products to be potted with electronic potting AB glue need to be kept dry and clean.

Electronic potting AB glue is measured according to the proportion, and the weighing is accurate. Please remember that the proportion is a weight ratio, not a volume ratio. After mixing A and B agents, they need to be fully stirred to avoid incomplete curing.

After the AB glue is evenly stirred, please fill it in time and try to use up the mixed glue within the available time.

After the electronic potting glue is poured, the glue will gradually penetrate the gaps of the product. Please perform a second filling if necessary.

During the curing process of electronic potting glue, please keep the environment clean to prevent impurities or dust from falling into the uncured glue surface.

After the electronic potting glue potting operation is completed, the unused glue should be tightened immediately and sealed for storage. When using it again, if there is a little crust on the seal, just remove it without affecting normal use.

Potting glue has excellent elasticity and toughness. It is not only important in the electronics industry, but also widely used in new energy, military industry, medical, aviation, shipbuilding, automobiles, high-speed rail and other fields.

More information or free samples or price quotations, please contact us via email: sales@yqxpolymer.com , or voice to us at: +86-28-8411-1861.

Some pictures and texts are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us to delete.