High-Performance Epoxy Resin Reinforced Carbon Fiber Composites: Driving Lightweighting in Electric Vehicles

Introduction

As the electric vehicle (EV) market grows rapidly in response to global environmental goals, the demand for lightweight, energy-efficient designs is critical. Lightweighting not only enhances vehicle range but also reduces energy consumption, supporting the transition to a greener automotive industry. High-performance epoxy resin reinforced with carbon fiber composites has become a key material in this movement, providing both the structural strength and weight reduction essential for modern EV design.

Key Role of Carbon Fiber Composites in EV Lightweighting

Carbon fiber composites are prized for their high strength-to-weight ratio, corrosion resistance, and durability, making them ideal for sectors such as aerospace and automotive manufacturing. However, while these composites offer several advantages, they also have inherent weaknesses, such as low interlayer shear strength and susceptibility to delamination. Addressing these issues is essential for enhancing their application in EVs, where material integrity under load is paramount.

Enhancing Carbon Fiber Composites with Epoxy Resin

Epoxy resins are crucial in reinforcing carbon fiber composites. High-performance epoxy resin offers excellent mechanical and thermal stability, significantly boosting interlayer shear strength and delamination resistance in composite materials. With a tailored resin formula and precision engineering, manufacturers can develop composites that meet EV industry demands for both reliability and safety.

Benefits of Epoxy Resin-Reinforced Carbon Fiber Composites in EVs

- Weight Reduction: The combination of epoxy resin and carbon fiber significantly reduces the weight of vehicle components without compromising strength, extending the range of electric vehicles by reducing the load on batteries.

- Enhanced Collision Safety: Epoxy-carbon composites absorb impact energy effectively, enhancing safety features in crucial areas such as the chassis, doors, and body panels.

- Durability and Corrosion Resistance: Epoxy resin’s thermal stability and resistance to harsh environmental conditions ensure long-lasting performance and reliability in EV applications.

Applications in EV Manufacturing

Epoxy resin-reinforced carbon fiber composites are applied in critical areas such as vehicle frames, underbodies, and doors. Engineers use simulation models to optimize these materials for specific applications, achieving lightweighting without compromising structural integrity. The resulting design innovations meet EV market demands while supporting safety, efficiency, and cost-effective manufacturing.

Conclusion

High-performance epoxy resin reinforced with carbon fiber composites is driving a new era of lightweight, sustainable electric vehicles. As the EV industry expands and consumer expectations for performance and eco-friendliness rise, these advanced materials offer manufacturers the versatility and efficiency needed to meet the challenges of modern electric vehicle design.

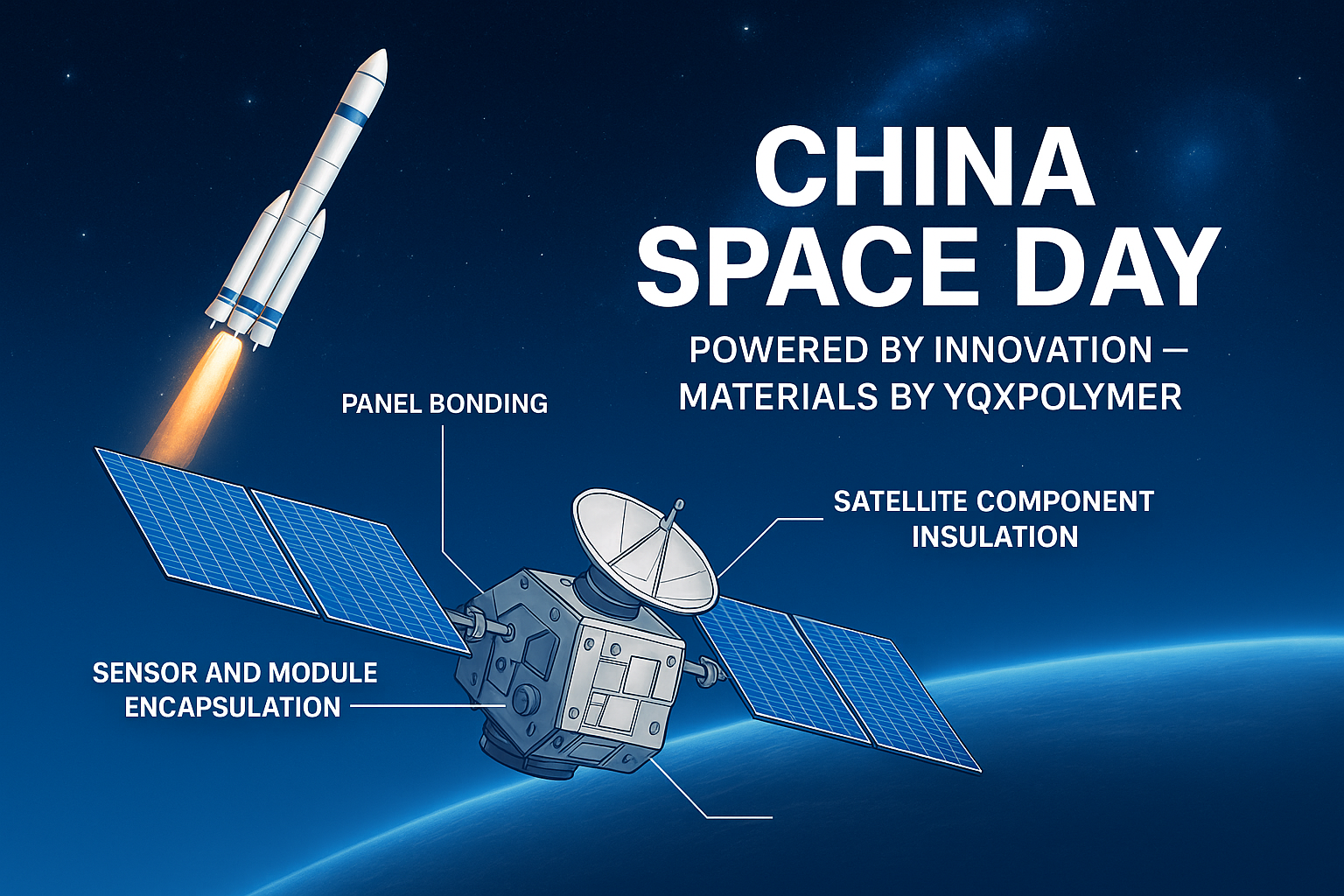

For more information about epoxy resin from YQXPOLIMER, please reach us at: sales@yqxpolymer.com or +86-28-8411-1816.

Some pictures and texts are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us to delete.