🌌 The Silent Hero of Space: Epoxy Resin’s Journey with YQXPOLYMER

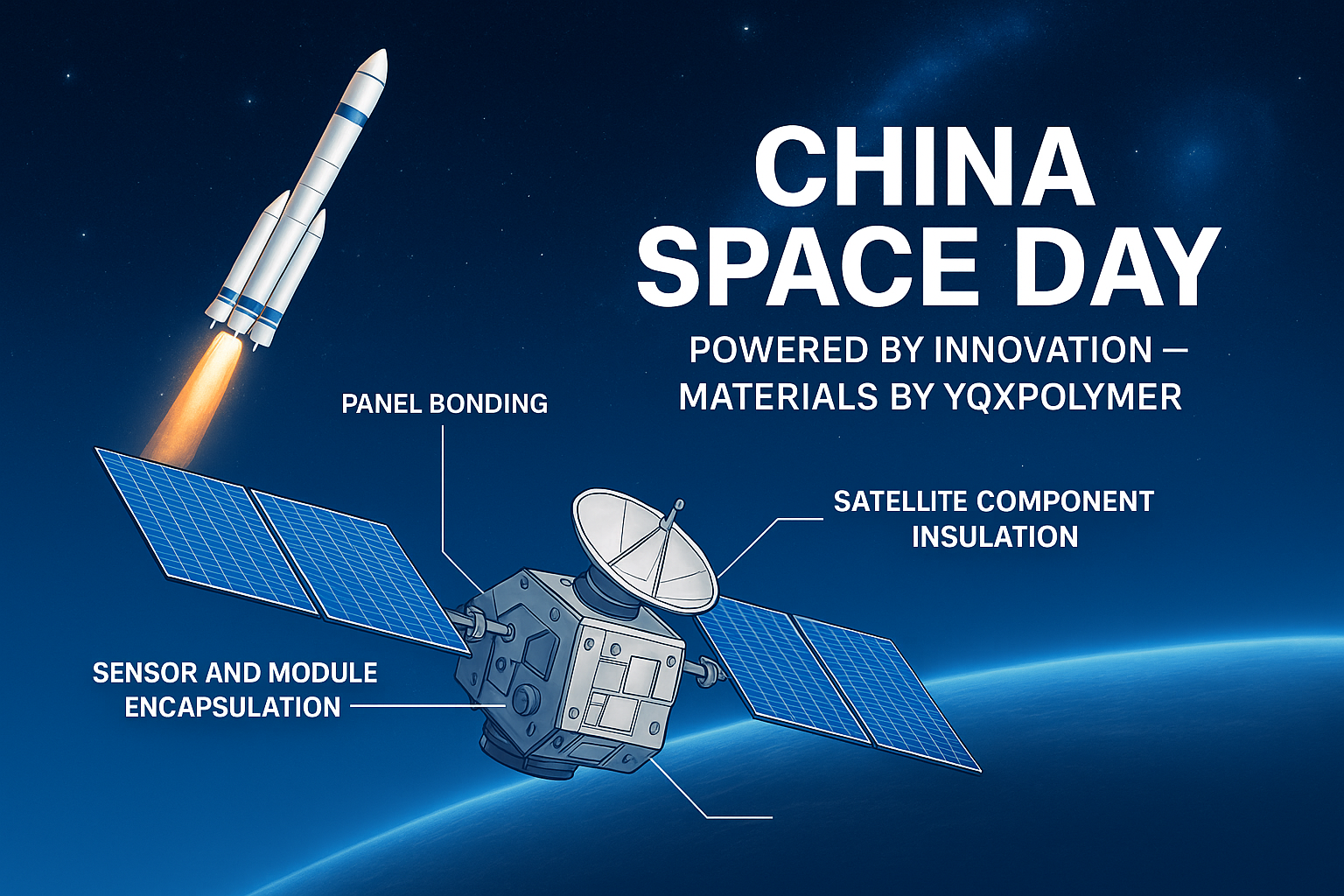

Every April 24, China Space Day celebrates the nation’s achievements in space exploration. Behind every rocket launch and space station module lies an invisible but vital force—epoxy resin. As a crucial adhesive and insulation material, it plays a key role in ensuring structural integrity, thermal protection, and electronic reliability. At the forefront of this materials revolution is YQXPOLYMER, whose high-performance epoxy solutions are making the leap from Earth to orbit.

🚀 1. Epoxy Resin in China’s Aerospace Projects

From the 1970s “Dongfanghong-1” satellite to today’s “Tiangong” space station, epoxy resins have played an essential role in bonding and protecting spacecraft components.

Used in:

- Bonding carbon fiber honeycomb panels and composites

- Encapsulation of sensitive electronics

- Structural adhesion in space modules

- Insulating and bonding within thermal control systems

YQXPOLYMER epoxy resins are designed to meet these exacting demands with:

- Low outgassing for vacuum environments

- High thermal resistance across -150°C to +200°C

- Excellent mechanical bonding and electrical insulation

✅ Example: YQXPOLYMER epoxy has been adopted by Chinese aerospace institutes for satellite antennas, solar panel bonding, and cabin structure assembly.

🌍 2. Global Aerospace and NASA’s Epoxy Journey

Epoxy resins are not only vital in China’s space missions—they’re also key materials in global programs from NASA to SpaceX.

- Apollo Missions: Used ablative epoxy-carbon composites for re-entry heat shields

- Space Shuttles & ISS: Employed epoxy composites for lightweight structural parts

- SpaceX Starship/Dragon: Adopt high-performance epoxy for modular and thermal sections

YQXPOLYMER’s advanced epoxy technology is also serving international aerospace clients, helping improve:

- Adhesive reliability

- Component durability

- Material weight savings

🛰 3. YQXPOLYMER: From Earth to Orbit, Enabling Next-Gen Aerospace Adhesion

With a focus on material innovation, low-VOC formulas, and long-term structural stability, YQXPOLYMER’s aerospace epoxy portfolio is trusted for:

- Satellite module bonding

- UAV (Unmanned Aerial Vehicle) insulation and sound dampening

- Thermal control base adhesives

- Anti-vibration and EMI protection

🎯 Whether protecting avionics during launch or keeping satellite panels intact through temperature extremes, YQXPOLYMER epoxy resins are the quiet force behind mission success.

✨ Conclusion: The Material Behind the Mission

As China and the world reach for the stars, epoxy resin remains one of the most dependable materials in the aerospace supply chain. With cutting-edge performance and proven reliability, YQXPOLYMER is not just keeping up—it’s helping spacecraft fly farther, safer, and lighter.