Introduction:

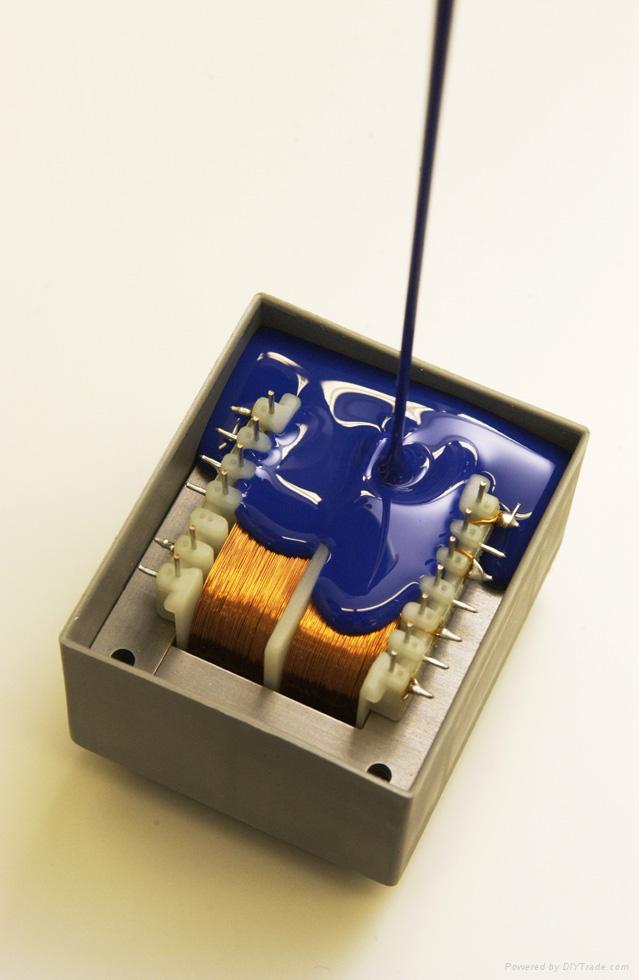

YQXPOLYMER proudly presents the YQX-142&161, a high-performance epoxy resin designed for high-power inductor applications. With its exceptional thermal conductivity, electrical insulation, and mechanical strength, this product ensures the durability and reliability of essential electronic components, particularly in the field of high-power electronics. Ideal for potting, bonding, and thermal management, YQX-142&161 guarantees consistent performance under demanding conditions.

Key Features and Benefits of YQX-142&161 Epoxy Resin:

- High Thermal Conductivity & Insulation:

YQX-142&161 offers superior thermal conductivity (1.0 W/m·K) and electrical insulation strength (over 16 kV/mm), making it an optimal choice for high-power inductors exposed to significant heat fluctuations during operation. Its effective thermal management helps prevent overheating in power supplies and related components. - Chemical & Environmental Resistance:

This epoxy resin is highly resistant to oils, gasoline, seawater, and humidity, ensuring long-lasting protection for your inductor potting applications. YQX-142&161’s robust resistance to environmental stress factors makes it ideal for automotive electronics and industrial machinery where exposure to harsh chemicals is common. - Superior Bonding Strength:

YQX-142&161 ensures excellent bonding strength with a flexural strength of 115-130 MPa and tensile strength at break of 75-95 MPa. This strong adhesive performance is crucial for the mechanical stability of high-power inductors, ensuring that the resin keeps critical components securely bonded under high stress and demanding conditions. - High-Temperature Performance:

With a heat deflection temperature of 140°C and a glass transition temperature of 133°C, this resin is engineered to excel in high-temperature environments, making it suitable for use in high-power electronics like transformers and inductors that operate in extreme heat. - Long-Lasting Durability:

YQX-142&161 exhibits outstanding performance even under aging, weathering, and physical stresses. Its low shrinkage rate (0.17%) and chemical resistance ensure that your high-power inductors continue to perform efficiently throughout their service life, reducing maintenance costs and ensuring operational reliability.

Applications of YQX-142&161 for High-Power Inductors:

YQX-142&161 epoxy resin is the go-to choice for potting and bonding critical electronic components, including high-power inductors, coils, and transformers. Key applications include:

- Power Supplies:

This epoxy resin ensures efficient thermal management and electrical insulation in power modules and inductor-based power supplies. - Electromagnetic Components:

Perfect for transformers, motors, and coil windings, ensuring long-term performance and protection under extreme operating conditions. - Automotive Electronics:

Suitable for automotive inductors and other high-power electrical components in vehicles, designed to withstand vibration, high temperatures, and demanding conditions. - Industrial Machinery:

YQX-142&161 offers reliable protection for inductors in heavy-duty machines and reactors operating under high stress, high humidity, and fluctuating temperatures.

Why Choose YQXPOLYMER’s YQX-142&161 Epoxy Resin?

YQXPOLYMER’s YQX-142&161 epoxy resin is engineered for performance, durability, and ease of use, offering a one-stop solution for all your high-power inductor needs. The resin’s unmatched thermal conductivity, electrical insulation, mechanical strength, and resistance to extreme conditions make it the optimal choice for high-power applications. With YQXPOLYMER, you can be assured of superior reliability, performance, and long-term operational efficiency.

For more information on how YQXPOLYMER’s epoxy resin can enhance your high-power inductor projects, contact us today!

Reach YQXPOLYMER, a leading Epoxy resin, Chlorosulfonated Polyethylene (CSM) manufacturer in China