Impact of Mixing Temperature on Montmorillonite/Epoxy Resin Composite Performance

Montmorillonite/Epoxy resin composites have gained significant attention in material science due to their exceptional properties, which make them suitable for a range of industrial applications. Recent studies have revealed that the mixing temperature during composite preparation plays a crucial role in enhancing the thermal and mechanical properties of these materials. In this article, we delve into the effects of mixing temperature on Montmorillonite/Epoxy resin composites, highlighting improvements in softening temperature, elasticity modulus, and overall performance.

Understanding the Role of Mixing Temperature

Mixing temperature directly influences the intercalation of Montmorillonite into the Epoxy resin matrix. As Montmorillonite layers are inserted between the resin molecules, the material’s structure becomes more refined, leading to enhanced properties. By optimizing the mixing temperature, the intercalation process becomes more effective, leading to a significant increase in the composite’s thermal stability and mechanical strength.

Key Findings from the Study

- Improvement in Softening Temperature: The softening temperature of the Montmorillonite/Epoxy resin composite increased by 11°C after intercalation. This enhancement signifies better heat resistance, making the material suitable for high-temperature applications.

- Increase in Elasticity Modulus: With the intercalation of Montmorillonite, the elasticity modulus of the composite material also showed noticeable improvement, indicating higher rigidity and better mechanical performance.

Advanced Characterization Techniques

To characterize the effects of mixing temperature on the composite’s performance, several advanced techniques were employed:

- X-ray Diffraction (XRD): XRD analysis was used to examine the interlayer spacing of the composite material. This technique provided insights into the structural changes occurring at different mixing temperatures.

- Dynamic Mechanical Thermal Analysis (DMTA): Different modes of DMTA were applied to assess the dynamic mechanical behavior of the intercalated composites. This analysis confirmed the positive impact of mixing temperature on the composite’s thermal and mechanical properties.

Practical Applications and Benefits

The enhanced properties of Montmorillonite/Epoxy resin composites make them ideal for applications in areas requiring both thermal stability and mechanical strength, such as automotive, aerospace, and electronics industries. By optimizing the mixing temperature during the preparation process, manufacturers can produce high-performance composites with tailored properties suited to specific application needs.

Conclusion

The impact of mixing temperature on the performance of Montmorillonite/Epoxy resin composites cannot be underestimated. As demonstrated through advanced testing and analysis, optimizing the mixing temperature leads to significant improvements in both thermal stability and mechanical strength. By leveraging these insights, industries can enhance the performance of composite materials, paving the way for new applications and innovations.

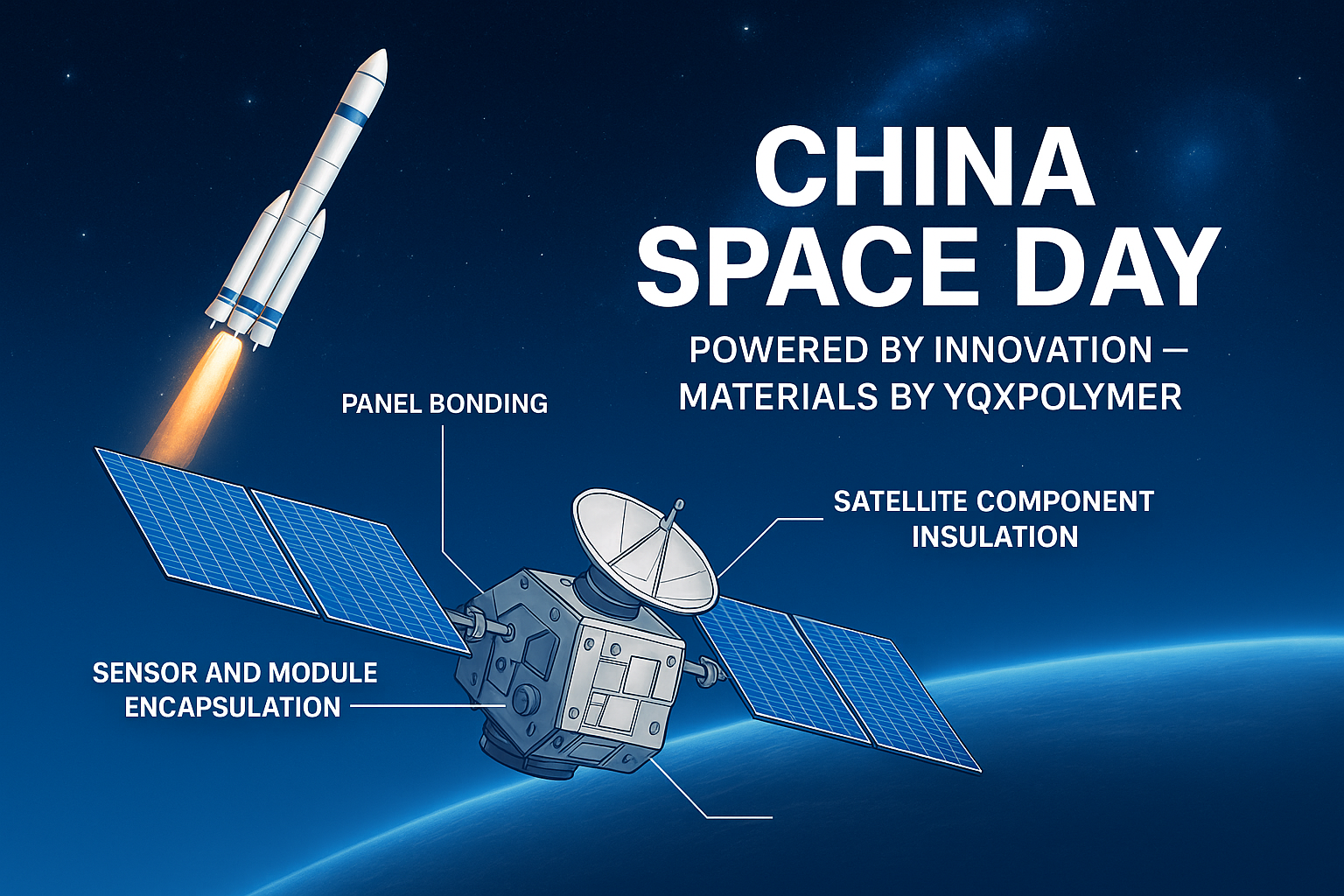

For more about YQXPOLMER epoxy resin, please reach us at: sales@yqxpolymer.com, or +86-28-8411-1861.

Some pictures and texts are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us to delete.