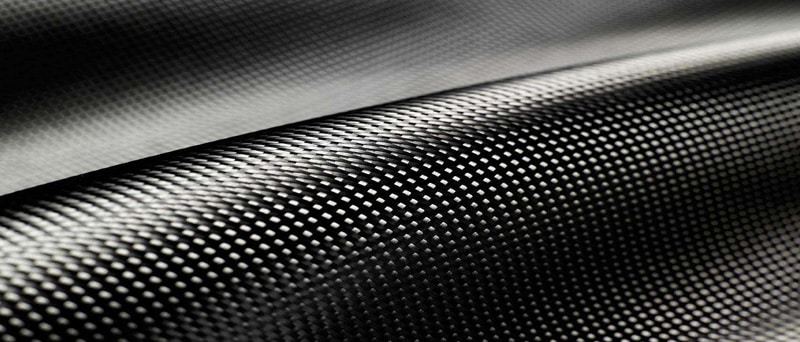

Carbon fiber prepreg is a high-performance composite material consisting of carbon fibers and a resin (epoxy resin) matrix. Carbon fiber is a high-strength, high-modulus fibrous material with excellent mechanical properties and chemical stability, while the resin matrix provides bonding and support between the fibers. Carbon fiber prepregs combine the advantages of carbon fire and resin matrix, and are lightweight, high strength, high stiffness, high temperature and corrosion resistant, and are widely used in aerospace, automotive, sports equipment, construction and other composite piping fields.

Material Composition

The main material composition of carbon fiber prepreg includes carbon fiber and resin matrix. Carbon fiber is made of organic fiber (such as polyacrylonitrile fiber) carbonized at high temperature, which has excellent mechanical properties and chemical stability. The resin matrix, on the other hand, is a polymer compound used to bond the carbon fibers together to form a monolithic structure. Common resin matrices include epoxy resins, phenolic resins, and polyimide resins.

Production process

The production process of carbon fiber prepreg composite pipes mainly includes the steps of carbon fiber surface treatment, resin impregnation and heat treatment. Firstly, surface treatment of carbon fiber is needed to increase its adhesion with resin matrix. Then, the treated carbon fibers are mixed with the resin matrix and impregnated to make the resin fully penetrate between the carbon fibers. Finally, the resin is cured by heat treatment to form a carbon fiber prepreg.

Characteristics

Carbon fiber prepreg has many excellent properties, such as lightweight, high strength composite pipes, high stiffness, high temperature resistance and corrosion resistance. Firstly, carbon fibre prepreg has extremely low density and weight, while having high strength and stiffness, making it an ideal lightweight and high strength material. Secondly, carbon fiber prepregs have excellent high temperature resistance and can maintain stable mechanical properties in high temperature environments. In addition, carbon fiber prepreg has good corrosion resistance and can be used for a long time in harsh environments.

Application Areas

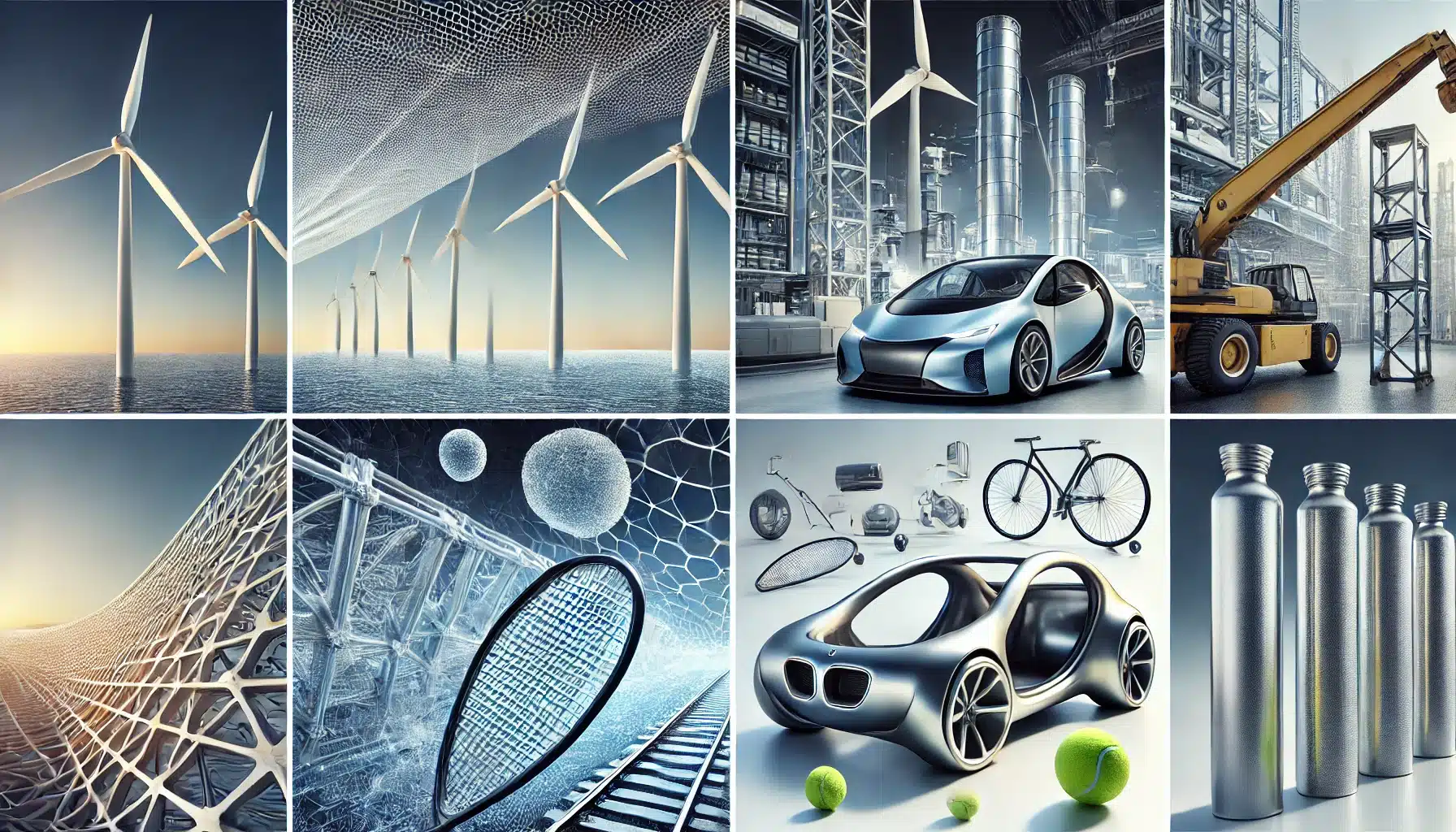

Carbon fiber prepreg is widely used in aerospace, automotive, sports equipment, construction and other fields because of its excellent composite pipe performance. In the aerospace field, carbon fiber prepreg is used to manufacture high-performance structural parts such as aircraft and satellites to reduce weight and improve performance. In the automotive field, carbon fiber prepregs are used to manufacture lightweight body, chassis and other components to improve fuel economy and driving stability. In the field of sports equipment, carbon fiber prepreg is used in the manufacture of high-grade bicycles, golf clubs, composite pipe fishing rods and other equipment to improve the strength and durability of the equipment. In the field of construction, carbon fibre prepregs are used in the manufacture of bridges, building facades and other structural components to improve the safety and durability of buildings.

Future development trend

With the continuous development of science and technology, carbon fiber prepreg will have a broader application prospect in the future. First of all, with the continuous improvement of carbon fiber preparation technology, the performance of carbon fibers will be further enhanced, thus promoting the performance of carbon fiber prepreg composite materials pipeline. Secondly, with the research and development of new resin matrix, the comprehensive performance of carbon fiber prepreg will be further optimized. In addition, the carbon fiber prepreg processing technology will continue to improve and innovate, providing more possibilities for the application of carbon fiber prepreg.

In conclusion, as a high-performance composite material, carbon fibre prepreg has a wide range of application prospects and important strategic significance. In the future, with the continuous development of carbon fiber preparation technology, resin matrix research and processing and molding technology composites pipeline technology, carbon fiber prepreg will be applied in more fields and promote the rapid development of related industries.

For more information about the epxory resin in carbon fiber, please reach us: sales@yqxpolymer.com or: +86-28-84111861.

Some pictures and texts are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact If there is any infringement, please contact us to delete.