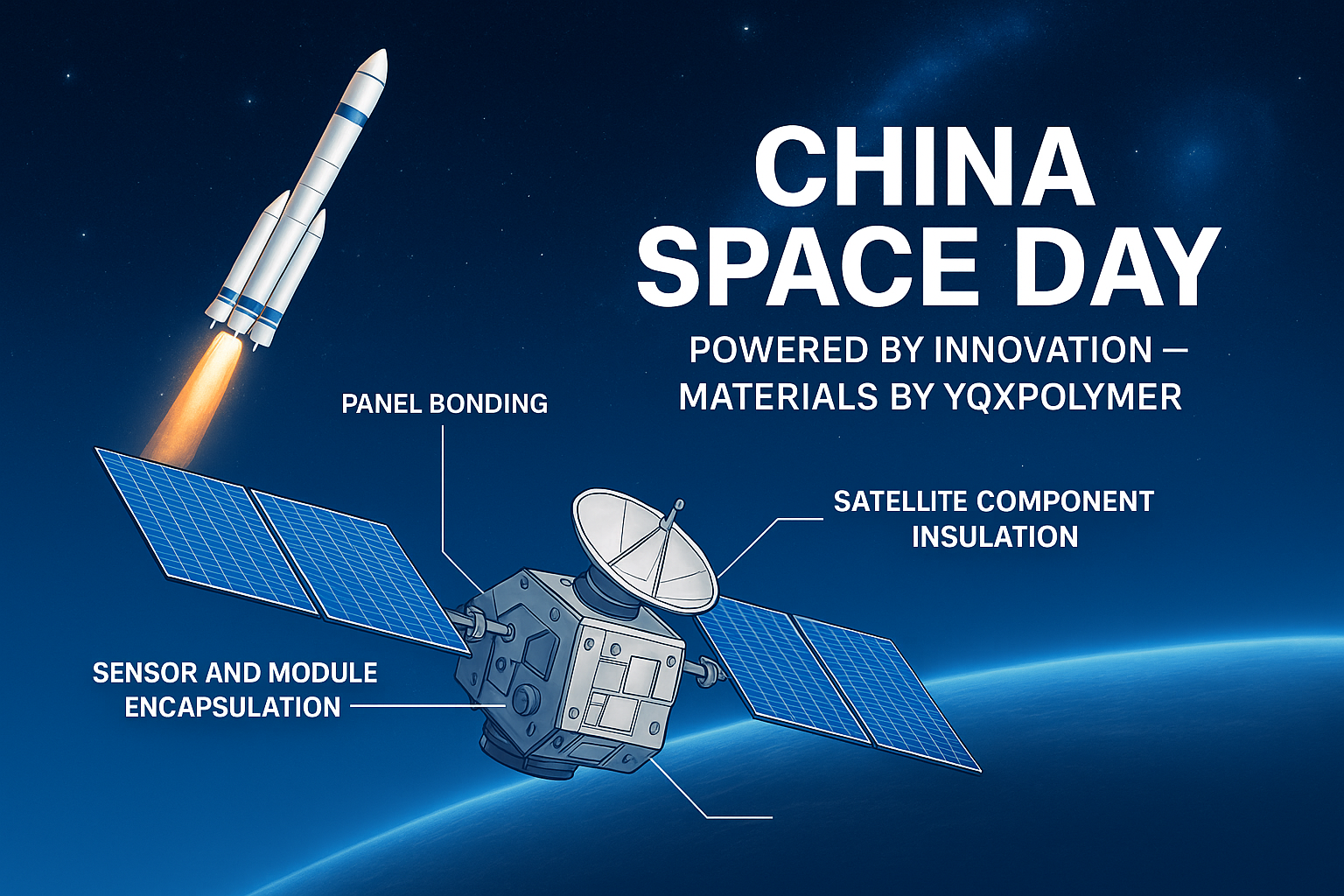

Epoxy resin is widely used in wind power, electronic and electrical, chemical anti-corrosion, aerospace, rail transportation, machinery manufacturing, ship transportation and other fields due to its strong adhesion, good corrosion resistance, strong electrical insulation and high mechanical properties.

The series of epoxy resin products for wind turbine blades mainly include vacuum infusion resin, hand lay-up resin and mold resin, etc., which have the characteristics of good mechanical properties, fatigue resistance, high and low temperature resistance, excellent mechanical properties, rapid prototyping, and typhoon resistance.

YQXPOLYMER 9201A/B epoxy resin is a product developed to meet the development needs of “lightweight” and “large-scale” wind turbine blades. YQXPOLYMER 9201A/B is an epoxy resin curing agent system specially designed for megawatt wind turbine blades, and it has long operating time and excellent mechanical strength and DNV certified.

Epoxy resin has excellent mechanical properties, chemical stability and corrosion resistance, and can be used as blade structural parts, connectors and coatings for wind power generation. In the supporting structure, skeleton and connectors of the blade, epoxy resin can provide high strength, high stiffness and fatigue resistance to ensure the stability and reliability of the blade. In addition, epoxy resin can also improve the wind shear resistance and impact resistance of the blades, reduce the vibration noise of the blades, and improve wind power generation efficiency.

The application of epoxy resin in wind turbine blade coating is also very critical. By coating epoxy resin on the blade surface, the wear resistance and UV resistance of the blade can be improved, and the service life of the blade can be extended. At the same time, it can also reduce the weight and resistance of the blades and improve the efficiency of wind power generation.

Epoxy resin needs to be used in many aspects of the wind power industry, with a wide range of applications. Currently, among the blade materials for wind power generation, epoxy resin is mainly used in wind turbine blades, the core component of the front end of wind turbines. It is used to make the main beams, shells, webs, blade molds and blade trailing edge bonding.

Due to the development needs of “lightweight” and “large-scale” wind turbine blades, the material properties of epoxy resin can optimize the basic parameters such as strength, stiffness and dynamic fatigue of wind turbine blades, making the wind turbine blades lighter, with longer service life, better maintenance performance and shorter maintenance cycle.

The epoxy resin curing agent contributes particularly crucially to the performance of the wind turbine blade system. Only curing agents with good structural properties can effectively enhance the overall strength of the epoxy resin and thereby enhance the blade strength. In addition, curing agents also have an important impact on process control of blade manufacturing. If the viscosity of the curing agent is too high, it will be difficult to operate. If the reaction speed is too fast, the opening time will be too short. During the curing process of the blade, the reaction will be exothermic and smoke will be emitted, posing risks to the operation. YQXPOLYMER 9201A/B has low mixing viscosity, excellent fiber wettability, long gel time and operable time, low exothermic peak, and excellent comprehensive mechanical properties after curing.

More information or free samples or price quotations, please contact us via email: sales@yqxpolymer.com , or voice to us at: +86-28-8411-1861.

Some pictures and texts are reproduced from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us to delete.